Summary

___________

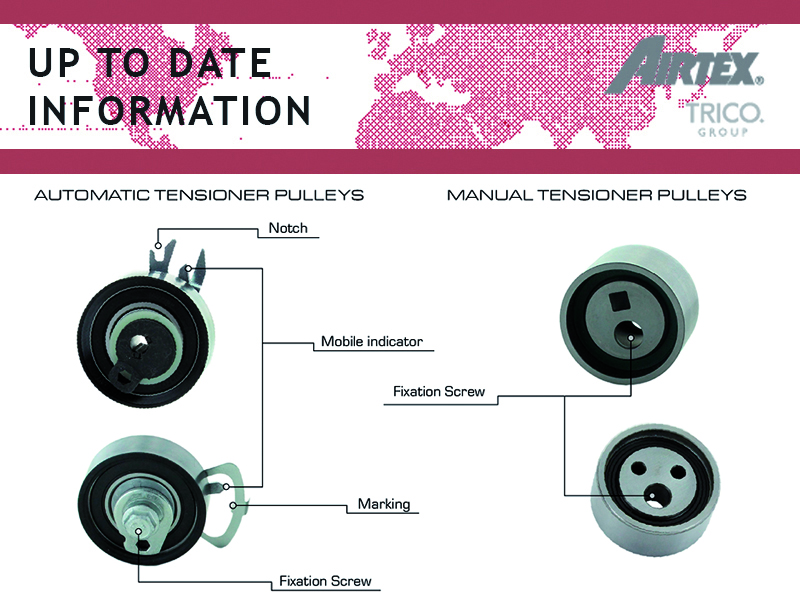

Automatic and Manual Tensioner Pulleys

___________

Adjusting Timing Belt tension

One of the most important preventive maintenance operations of the vehicle is the replacement of the timing belt and the water pump. In this operation it is key to apply the correct tension on the belt, and the component in charge of it is the tensioner. It is basically an eccentric pulley that when spins applies pressure on the belt.

Nowadays automatic tensioners are more used and each manufacturer has a different design, but generally all have a mobile indicator and a notch in an easily visible area. Tensioning the belt is easy in these cases, since the tensioner must be rotated in the indicated direction until the mobile indicator is aligned with the notch. Once this is done, the screw or nut is fixed to the indicated torque, the crankshaft is rotated two complete turns to distribute the tension along the entire belt and it is checked again that the indicator is aligned. If is not the case, the operation must be repeated until the indicator is brought to the correct position. Another version of these components are manual tensioners, which can still be found in many engine configurations.

For the tensioning of the belt with this type of elements the procedure is similar, with the difference that the tension of the belt must be checked after turning the crankshaft twice. Some manufacturers determine to measure the tension of the belt with a sphygmomanometer at some specific point on the belt and establish the values it must have to ensure correct tensioning of the belt.

A tight belt with overvoltage can cause deterioration and wear of the belt, and can affect the tensioner, roller and water pump bearings, blocking these components. Equally dangerous is insufficiently tensioned mounting of the belt, as a buckling phenomenon occurs on the belt, causing similar damage to the belt and other components.

It is also necessary to check the alignment of other elements such as the camshaft sprockets, crankshaft or injection pump, since it could cause a forced movement of the belt, which could damage the tensioners, rollers or even the water pump.