Summary

___________

Universal High Pressure Fuel Pumps

As a continuation of the previous article on AIRTEX low pressure universal pumps with solenoid technology, we complete the family with high-pressure in-line universal pumps.

Although these types of pumps were developed in the 1980s and were the previous step to modules and submerged turbine pumps, today they are still widely used in the Aftermarket due to their performance.

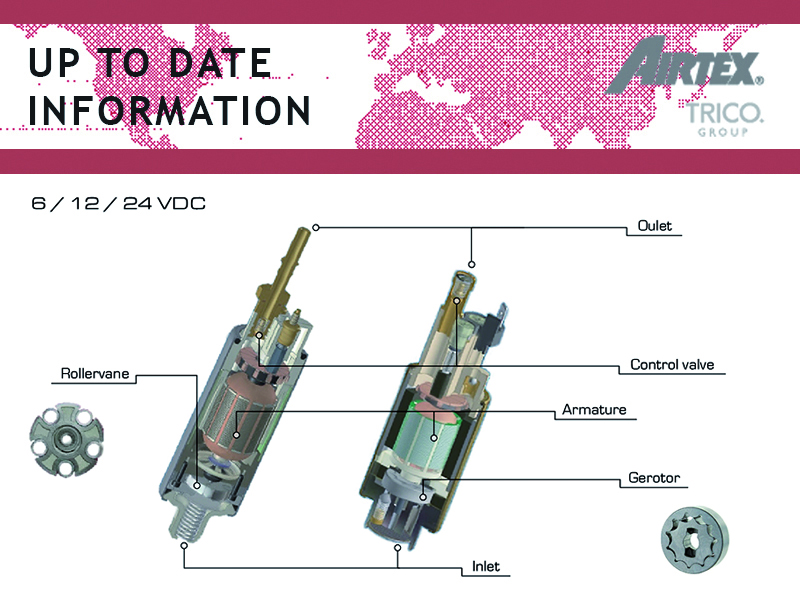

In the AIRTEX catalog we have pumps that work at a constant voltage of 12VDC, although for more specific applications there may be pumps that work at 6VDC and 24VDC.

Depending on the model, they can have a working pressure that ranges from 3.5 to 7 bar pressure and a flow of 117 to 132 l / h. Universal high-pressure pumps are positive displacement volumetric pumps.

This type of pumps have a roller vane type rotor or roller blade as shown in the image that rotates in solidarity with a direct current motor (armature) located inside the pump body. By rotating the rotor, a pressure increase in the fluid inside the pump takes place and induces the movement of fuel flowing from the tank to the engine.

In addition to the roller vane rotor, there is another variant called Gerotor that works similarly, but with different geometries. The gerotor uses a unique eccentric gear and rotor mechanism that squeezes fuel into the pump to create high-pressure with limited pulsation.

The universal high-pressure pumps are assembled on both light and industrial vehicles for diesel and gasoline, and their list of applications is very extensive and varied.